http://tuxgraphics.org/electronics

A Digital DC Power Supply (programmable bench power supply unit), hardware version 3.0

![[Illustration]](../../common/images2/article10051/ddcp-title.jpg)

Abstract:

A good, reliable and easy to use bench power supply unit is probably the most

important and most used device in every electronic lab.

A proper electronically stabilized

bench power supply unit is an important but also expensive device.

Using a microcontroller based design we can build a power

supply which has a lot of extra features, is easy to build and very affordable.

The tuxgraphics digital DC power supply has been a very

successful product and this is now the third generation.

It is still based on the same idea as the first version but

comes with a number of good improvements.

_________________ _________________ _________________

|

Introduction

This bench power supply unit is less complex than most other circuits but

has a lot more features:

- The display shows the actual measurement values for voltage and current.

- The display shows the pre-set limits for voltage and current.

- Only standard components are used (no special chips).

- Only one power source is needed (no separate negative supply voltage for operational

amplifiers or control logic)

- You can control the power supply from a PC. You can read

current and voltages and you can set them with simple commands. This is very

useful for automated testing.

- A small button pad is available to directly enter the desired voltage and max.

current.

- It is really small but powerful.

How was it possible to remove components and add more features? The trick is to

move functionality which is normally based on analog components like operational

amplifiers into the microcontroller. In other words the complexity of the

software and algorithms is higher but hardware complexity is reduced. This

reduces the overall complexity for you as the software can just be copied.

The basic electrical design idea

A common misconception about a digital power supply is that people assume everything to be digital and don't understand how

this could possibly work with a circuit based on a microcontroller. We want

a clean and stable analog voltage as output and for this we use analog components. Only analog components are fast

enough to remove ripples due to load changes or any remaining 50/60Hz noise.

The emitter voltage on a transistor is related to the voltage on the base and not the input voltage on the collector. The main current flows however from C to E.

This simple circuit produces a clean DC voltage. It removes noise coming in through the collector pin and controls load changes on the emitter side.

In other words our digital power supply has a completely analog control system

for fast respose to load and voltage changes and we overlay

a second digital control system

for the more fancy features that a bench top power supply needs.

Let's remove the battery from that circuit and build the simplest possible electronically stabilized power supply.

It consists of 2 basic parts: a transistor and a reference voltage generated

with a Z-diode.

The output voltage of this circuit is Uref - 0.7V. The 0.7V is approximately

the voltage drop between B and E on the transistor. The Z-diode and

the resistor generate a reference voltage which is stable, even if the input

fluctuates and is noisy. The transistor is needed to handle higher currents

than the Z-diode and resistor alone can provide. In this configuration the

transistor just amplifies the current. The current which the resistor and

Z-diode need to provide is the output current divided by hfe (hef is a number

which you can lookup in the datasheet of the transistor).

What are the problems with this circuit?

- The transistor will die when there is a short circuit on the output.

- It provides only a fixed output voltage.

These are quite severe limitations which make this circuit unusable but this

circuit is

still the basic building block of all electronically regulated power supplies.

To overcome those problems you need

some "intelligence" which will regulate the

current on the output and a variable reference voltage. That's all (... and

this makes the circuit much more complex).

For the last few decades people have used operational amplifiers to provide this

intelligence. Operational amplifiers can basically be used as analog calculators to

add, subtract, multiply or logically "or" voltages and currents.

Today microcontrollers are so fast that all this can easily be done in software.

The beauty is that you get as a side effect a voltmeter and an amperemeter

for free. The control loop in the microcontrollers has to know voltage and

current values anyhow. You just need to display them.

What we need from the microcontroller are:

- A AD-converter to measure voltage

and current all the time

- A DA-converter to drive our power transistor (provide the

reference voltage)

The problem is that the DA-converter needs to be very fast. If there is a short

circuit detected on the output then we must immediately reduce the voltage

on the basis of the transistor otherwise it will die. Fast means within

milliseconds (as fast as an operational amplifier).

The ATmega8 has an AD-converter which is more than fast enough but it has

at first glance no DA-converter. It is possible to use pulse width modulation (PWM)

and an analog low pass filter to get an DA-converter but PWM alone is much too slow

to implement the short circuit protection in software. How to build a fast

DA-converter?

The R-2R ladder

There are many ways to build a digital to analog converter but we need a

fast and cheap one which can easily interface to our microcontroller.

There is a DA-converter circuit known as "R-2R ladder". It consists of resistors

and switches only. There are two types of resistors. One with the value R and one

with twice the value of R.

The above shows a 3 bit R2R-DA-converter. The control logic moves the switches

between GND and Vcc. A digital "one" connects the switch to Vcc and a digital

"zero"

to GND. What does this circuit do? It provides voltages in steps of Vcc/8.

In general the output voltage is Z * (Vcc/(Zmax+1) where Z is the digital

number. In the case of a 3 bit AD converter this is: 0-7.

The inner resistance of the circuit as seen from the output is R.

Instead of using separate switches we can connect the R-2R ladder to the

microcontroller output lines.

Generating a variable DC signal with PWM (pulse width modulation)

Puls width modulation is a method

where you generate pulses and run them thru a low pass filter

with a cut off frequency much lower than the pulse frequency.

This results in a DC signal and the voltage depends on the width

of those pulses.

Using PWM to generate a variable DC voltage.

The atmega8 provides in hardware

16bit PWM. That is: you could theoretically have a 16bit DAC with

just very few components.

In order get a true DC signal out of a PWM signal one has to average

it out using a filter and that can be a problem at high resolutions.

The more accuracy you have the lower the frequency of the PWM signal.

This again means you need big capacitors and the response time is

very slow. The first

and second generation of the digital DC power supply had a 10bit

R2R-ladder DAC. That is: the output could be set in 1024 step.

If you run the atmega at 8MHz and use a 10bit PWM DAC then

the PWM signal pulses have a frequency of 8MHz/1024=7.8KHz. To

get a somewhat good DC signal out of this you need to filter it

with a second order low pass filter of 700Hz or less.

You can imagine what happens if you use 16bit PWM. 8MHz/65536=122Hz.

One would need a 12Hz low pass.

Combining R2R-ladder and PWM

It is possible to combine the idea of the PWM and the R2R-ladder.

In this design we will use a 7bit R2R-ladder combined with a 5bit

PWM signal. With a 8MHz system clock and 5bit resolution we will get

a 250KHz signal. 250KHz can even be converted with small capacitors

into a DC signal.

The original version of the tuxgraphics digital DC power supply had

a 10bit DAC based on the R2R ladder. In this new design we use

R2R-ladder and PWM with a total resolution of 12bit.

Oversampling

At the expense of some processing time one can increase the resolution

of an analog to digital converter (ADC). This is called oversampling.

Four fold oversampling results in double resolution. That is: 4 consecutive

samples can be used to get twice as many steps on the ADC.

The theory behind oversampling is explained in the PDF document which

you can find at the end of this article.

We use

oversampling for the voltage control loop. For the current control loop we use

the original resolution of the ADC as fast response times are here more

important than resolution.

A more detailed design

So here is now a more detailed design of the above circuit.

A few technical details are still missing:

- The DAC (digital to analog converter) can not provide the current to drive

the power transistor

- The microcontroller operates at 5V so the maximum output of the DAC is 5V

which means that the maximum output voltage behind the power transistor will be

5-0.7=4.3V .

To fix this we must add amplifiers for current and voltage.

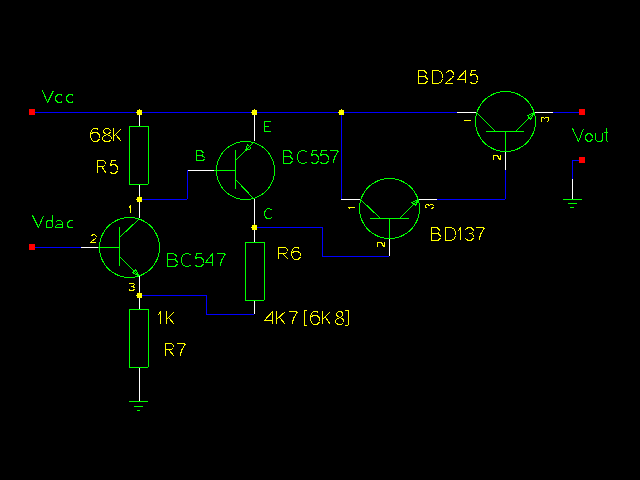

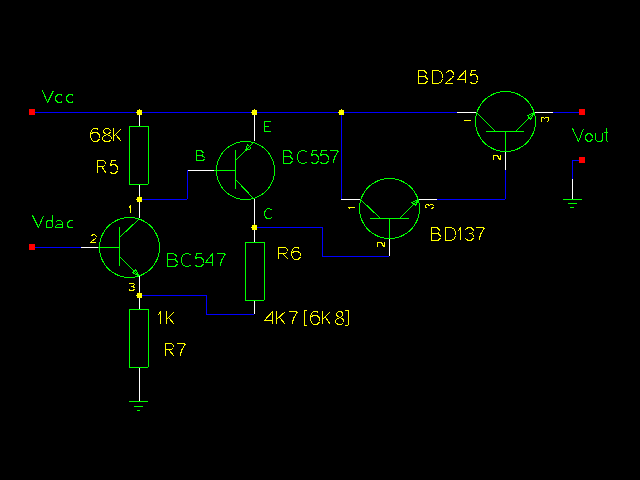

Adding an amplifier stage to the DAC

When adding amplifiers we must keep in mind that those must work with large

signals. Most amplifier designs (e.g for audio) are done under the assumption

that the signals will be small compared to the supply voltage. So forget all the

classic books about transistor amplifier design.

We could use operational amplifiers but those would require extra positive and

negative supply voltages which we want to avoid.

There is also the additional requirement that the amplifier must go from zero

voltage to a stable state without oscillating.

In words there must not be any short oscillation or output peek when you switch

on the power supply.

The below circuit shows an amplifier stage which is

suitable for this purpose.

We start with the power transistor. We use a BD245 (Q1). According to the datasheet

this transistor has

a hfe=20 at 3A output. It will therefore draw about 150mA on the basis.

To amplify the current we use

a configuration known as "Darlington transistor". For this we put a medium power

transistor

in front. Those have typically a hfe value of 50-100. This will reduce the current needed to

less than 3mA (150mA / 50).

3mA are manageable with small signal transistors like BC547/BC557. Those

small signal transistors are then very good for building a voltage amplifier.

For 30V output we must at least amplify the 5V from the DAC by a factor of 6.

For this we combine a PNP and an NPN transistor as shown above. The voltage amplification

factor of this circuit is:

Vampl= (R6 + R7)/R7

The power supply shall be

available in 2 version: Max 30 output and max 22V output. A combination of 1K

and 6.8K gives a factor of 7.8 which is good for the 30V version and has some

room for possible losses due to higher currents (our formula is linear. The reality

is non-linear). For the 22V

version we use 1K and 4.7K.

The inner resistance of the circuit as seen on the Basis of BC547 is:

Rin=hfe1 * S1 * R7 * R5 = 100 * 50 * 1K * 47K = 235 MOhm

- hfe is about 100 to 200 for a BC547 transistor

- S is the slope of the amplification curve of a transistor and is

about 50 [unit=1/Ohm]

This is more than high enough for the connection to our DAC which has a inner resistance of 5K.

The inner equivalent output resistance is:

Rout= (R6 + R7) / (S1 + S2 * R5 * R7) = about 2 Ohm

Low enough to drive the following transistor Q2.

R5 ties the basis of BC557 to

the emitter which means "off" for the transistor until the DAC and BC547 come up.

R7 and R6 tie the Basis of Q2 initially to ground which shuts the output

darlington stage down.

In other words every component in this amplifier stage is initially off.

This means we will not get from those transistors any oscillations or output

peeks at power on or power off. A very important point. I have seen expensive

industrial power supplies which produced a voltage peek at power off. Such a

power supply is definitely to be avoided as it can easily kill sensitive

circuits.

The limits

From previous experience I know that some readers would like to

"customize" the circuit a bit. Here is a list of hardware limits

and how to overcome them:

BD245B: 10A 80W. The 80W are however at a temperature of 25'C

In other words add a safety margin and calculate with 60W-70W:

(Max input voltage * Max current) < 65W

You can add a second BD245B to go up to 120W. To ensure

that the current distributes equally add a 0.22 Ohm resistor

into the Emitter line of each BD245B.

The same circuit and board can be used. Mount the transistors

on a proper aluminum cooler and connect them with short

wires to the board. The amplifier can drive a second power transistor

(that's the maximum) but you might need to adjust the

amplification factor.

Current measurement shunt:

We use a 0.75 Ohm resistor with 6W. This is good enough

for about 2.5A of output (Iout^2 * 0.75 <= 6W). Use a resistor

with more watts for higher currents.

Power sources

You can either use a transformer, rectifier and big capacitors or

you can try to get a 32/24V laptop power supply.

I went for the later option. Those laptop power supply "bricks" are

sometimes sold very cheap (over stock) and some of them provide

70W at 24V or even 32V DC.

Most people will probably go for a transformer because those are

very easy to get.

22V 2.5A version: you need a 18V 3A transformer, a rectifier

and a 2200uF or 3300uF capacitor. (reason: 18 * 1.4 = 25V)

30V 2A version: you need a 24V 2.5A transformer, a rectifier and

a 2200uF or 3300uF capacitor. (reason: 24 * 1.4 = 33.6V)

It does not harm to buy a transformer which can provide more ampere.

A power diodes bridge with 4 diodes which are specified for a

low voltage drop (e.g BYV29-500) gives a good

rectifier.

You can also

use a "heavier" transformer.

Check your circuit for proper insulation. Make sure that it is not possible to

touch any part that may carry 110V/230V even when the case is open.

Connect all metal parts of the chassis to earth (not to GND of the circuit).

Transformers and laptop power supply bricks

If you want to use two or more power supplies in a chain

to get positive and negative voltages for your circuit then

it is important that the transformer is really insulated. Be careful

with laptop power supply bricks. They are nice and small but some of them

may connect the minus pin on the output to the earth pin on the input.

This will then cause a short ciruit via the earth wire if you use

two power supplies in a chain.

Other voltages and current limits

The two provided configurations are 22V 2.5A and 30V 2A. If you want

to build a version with other (lower) output voltages or current limits

then just edit the hardware_settings.h file.

Example: To build a 18V 2.5A version you just edit the hardware_settings.h

file and change the maximum output voltage to 18V.

You can then use a 20V 2.5A power source.

Example: To build a 18V 1.5A version you just edit the hardware_settings.h

file and change the maximum output voltage to 18V and the max. current to

1.5A.

You can then use a 20V 1.5A power source.

Testing

The last component to solder to the board should be the microcontroller.

Before you insert it I would recommend to do some basic hardware tests:

Test1:

Connect some power supply (at least 10V) to the power input of the circuit and

check that you get 5V DC behind the voltage regulator.

Test2: Measure the output voltage. It should be 0V (or near zero, e.g 0.15V, and

it will go to zero if you put a "load" of 2K to 5K on the output.)

Test3: Solder the microcontroller to the board and load the LCD test software by running the

commands in the directory of the unpacked digitaldcpower tar.gz package.

make test_lcd.hex

make load_test_lcd

You should see "LCD works" on the display.

Now you can load the final software.

A word of warning for further testing with the final software: Be careful with short

circuits until you have tested the current limitation function. A save way to

test the current limitation is to use a low Ohm resistor, e.g a car bulb.

Set a low current limit, e.g 30mA at 10V. You should see the voltage

go down immediately

to almost zero once you connect the bulb on the output. There is still a fault

in the circuit if it does not go down. The car bulb will protect the power

supply circuit even if there is a fault as it is not a full short circuit.

The software

This section will give you insights as to how the software

works and you can use the knowledge to do modifications.

However be aware that the short circuit protection is also only

software. If you make a mistake somewhere then this protection

may not work. If you cause then a short circuit on the output

your hardware may go off in a cloud of smoke. To avoid this

you should use a 12V car bulb (see above) to test the short circuit

protection.

Now a bit about the software structure.

First look at the main program (file main.c, download at the end of this

article) you will see

that there are only a few lines of initialization code executed

at power on and then the software enters an endless loop.

There are really 2 endless loops in this software.

One is the main loop ("while(1){ ...}" in file main.c) and the

other one is the periodic interrupt from the Analog the Digital

Converter (function "ISR(ADC_vect){...}" in file analog.c).

During initialization the interrupt is configured to execute every

104μ Sec. All functions and code that is executed runs in

the context of one of those tasks (task the name for a process

or thread of execution in a real time OS, so I use this word here even if

there is no OS).

![[priorities]](../../common/images2/article10051/tasks.gif)

The interrupt task can stop the execution of the main loop at

any time. It will then execute without being interrupted and

then execution continues again in the main loop at the place

where it was interrupted. This has two consequences:

- The code in the interrupt must not be too long as it must

finish before the next interrupt comes. What counts here are

the amount of instructions in machine code. A mathematical

formula, which can be written as just one line of C-code may

result in hundreds of lines of machine code.

- Variables that you share between interrupt code and code

in the main task may suddenly change in the middle of

execution.

All this means that complex things like updating of the

display, checking of push buttons, conversion of ampere and

volt values to internal units etc ... must be done in the main

task. In the interrupt we execute only things that are time

critical: Current and voltage control, overload protection and

setting of the DAC. To avoid complex mathematics all

calculations in the interrupt are done in ADC units. That is

the same units that the ADC produces (integer values from

0...1023 for current and 0..2047 for voltages).

This is the basic idea of the software. I will also explain

what you find in which files and then you should be able to

understand the code (given that you are familiar with C).

Software: Which file contains what

main.c -- this file contains the main program. All initialization is

done from here.here. The main loop is also implemented here.

analog.c -- the analog to digital converter and everything that

runs in the context of the interrupt task can be found here.

dac.c -- the digital to analog converter. Initialized from ddcp.c but

used only from analog.c

kbd.c -- the keyboard code

lcd.c -- the LCD driver. This is a special version which will not need

the RW pin of the display. It uses instead an internal timer

which should be long enough for the display to finish its task.

Loading and using the software

To load the software into a microcontroller you need a programmer such

as the avrusb500. You can download the ziped software archives

at the end of the article.

Edit the file hardware_settings.h and adjust it according to the hardware.

Here you can also do calibrations of voltmeter and amperemeter. The file

is well commented.

gedit hardware_settings.h

Connect the programmer cable and power on the circuit.

Then run:

make fuse

This will set the clock frequency of the microcontroller to 8MHz. The

software is designed for this frequency.

make

This will compile the software.

make load

This will load the software.

Control of the power supply unit from any PC (Win, Linux, Mac,...)

This power supply can be controlled by 5 buttons on the front pannel

or via a USB connection from a PC.

The power supply to USB interface is an optional add-on card.

![[ddcp to usb]](../../common/images2/article10051/usb-interface.jpg)

Digital power supply USB interface with galvanic separation.

Note: we finally decided to use a USB-B socket. The power

supply shown in the title image of this article has a different

connector as it was built before that decision was made.

The card offers galvanic separation

such that you can use this power supply relative to

any reference point (e.g build two power supply units and use

one as negative and one as positive power supply).

Galvanic separation is achieved buy using two opto-coupler chips.

The information is transmitted with light pulses inside the chip

but there is no electrical connection between the receiving and

transmitting side.

The power supply shows then up as a virtual com-port on your computer

and you can connect to it with any serial terminal.

HyperTerminal is a popular windows serial terminal software

but it is a bit complicated to use. I prefer putty (http://www.chiark.greenend.org.uk/~sgtatham/putty/). For Linux I can recommend

picocom

(http://code.google.com/p/picocom/) It is simple and straight forward to use. Just run the command

"picocom -l -b 9600 /dev/ttyUSB0" and to disconnect you type Crtl-a Crtl-x.

The port settings are as follows:

baudrate : 9600

parity : none

flowcontrol: none

stopbits : 1

databits : 8

![[serial terminal]](../../common/images2/article10051/screenshot-cmd-interface.gif)

Command interface for the power supply

The power supply accepts simple commands like "u=.." to set the voltage

or "i=.." to set the current. There is as well a "help" command which

explains all commands and the syntax. The command prompt shows the

same information that can be seen on the LCD display of the power supply.

You can control the digital power supply by commands. A number

of commands are provided for this purpose. They are at the moment

available for Linux, Mac and Windows:

ddcp-script-ttyinit - initialize the COM port (run this once at

at the beginning)

ddcp-script-getval - get current values (same as you see on the LCD)

ddcp-script-setval - send a command to the power supply

With this you can write a shell script or batch file

to control the power supply or print current values for current and voltage:

#!/bin/sh

dev="/dev/ttyUSB1"

# initialize the com port

ddcp-script-ttyinit "$dev"

#

echo "current settings are:"

ddcp-script-getval "$dev"

#

echo "setting voltage to 3.3 V"

ddcp-script-setval "u=33" "$dev"

#

echo "wait a bit, it takes a moment for the display values"

echo "to adjust as they are polled in intervals by the avr software."

sleep 1

echo "the new settings are:"

ddcp-script-getval "$dev"

The buttons

The power supply has 4 button for local control of voltage and max. current.

The 5-th button is to store the settings permanently in an eeprom such that

it will come up with identical settings the next time you power it on.

![[buttons]](../../common/images2/article10051/buttons.gif)

The local control button pad.

With U+ you can increase the voltage and with U- you decrease it. When you

hold the button then it will step and after a while "run" faster to make

it easy to change the voltage in large steps. The I+ and I- buttons work

the same way.

The display

This is how the display looks like:

![[display]](../../common/images2/article10051/display.png)

The fields in the LCD display area. The real measured

values and the set values are always shown at the same time.

The arrow on the right indicates that currently the configured voltage

is the limiting factor. Should a short circuit occur on the output or

the connected device draws more current then the arrow will flip to the

bottom line and indicate that the configured max. current has become the limiting

factor.

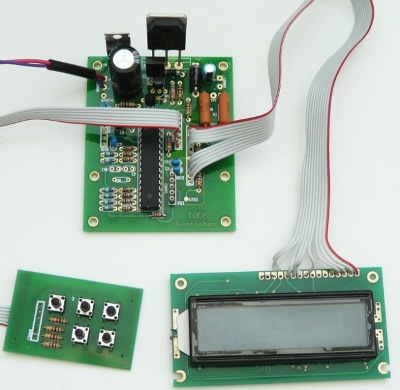

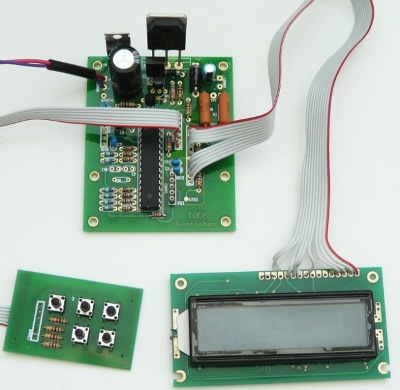

Some pictures and ideas

Here are some pictures from the power supplys which I have build.

The circuit. Very small but with more features and more powerful than many

other power supply circuits.

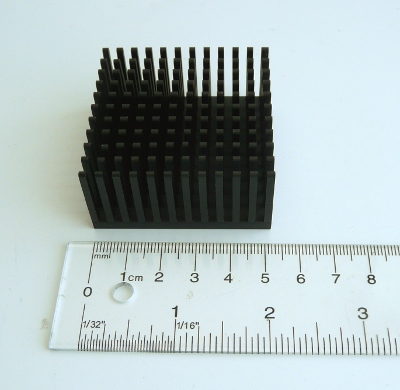

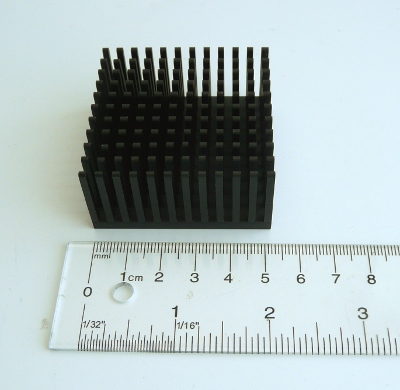

An old Pentium5 aluminium cooler is a good choice for this power supply. It is compact

and very efficient. A cooler that provides about 1K/W is sufficient. You might as well

consider to under dimension it a bit. It will normally be very rare that you operate it permanently

at maximum current with a low output voltage.

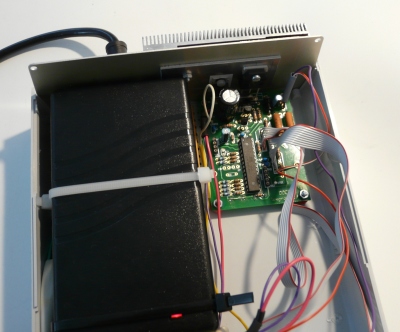

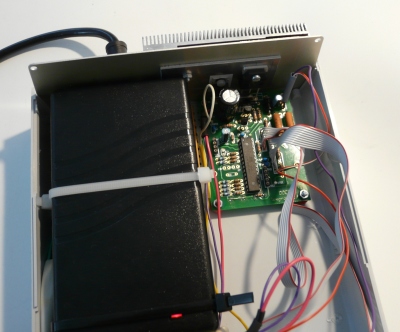

Installing the components in a case

The final power supply unit.

The final power supply unit. -With a green display-

... and with a blue display in a different case.

Blue displays are bit difficult to

photograph.

It looks even better in reality than here on the photo.

|

Have fun! I am sure you will like this power supply unit. I use it a lot

and every day.

References/Download

© Guido Socher, tuxgraphics.org

2015-02-25, generated by tuxgrparser version 2.57

![[Illustration]](../../common/images2/article10051/ddcp-title.jpg)

![[priorities]](../../common/images2/article10051/tasks.gif)

![[ddcp to usb]](../../common/images2/article10051/usb-interface.jpg)

![[serial terminal]](../../common/images2/article10051/screenshot-cmd-interface.gif)

![[buttons]](../../common/images2/article10051/buttons.gif)

![[display]](../../common/images2/article10051/display.png)