home |

electronics |

toolbox |

science club |

tuxtalk |

photos |

e-cards |

online-shop

Content:

By Guido Socher

<guido_at_tuxgraphics.org>

|

A simple digital thermometer

![[Illustration]](../../common/images2/article07051/I2Ctemp-20074-title.jpg)

Abstract:

This is an

update of two articles which I wrote in 2005 about a small

digital thermometer. The circuit seems to be very popular because

it is so simple and still has a very useful and practical

application. It is the perfect circuit to get started with AVR

microcontrollers.

This updated article replaces the articles from 2005 and

simplifies the software as well as the hardware. The original

documents from 2005 are linked at the end of this article in case

you still need them.

This thermometer can be used as a standalone thermometer with LCD

display or it can be read out with a PC running Linux, Windows,

MacOSX or solaris. BSD Unix and others are probably also possible

to use for reading the temperatures. No special drivers are needed.

The hardware described here can be ordered from http://shop.tuxgraphics.org

_________________ _________________ _________________

|

Introduction

When you use such an advanced device as a

microcontroller to measure analog or digital signals then you

want of course interfaces to evaluate the data or send commands

to the microcontroller. In all the articles presented here in the

past we always used rs232 communication with the UART that is

included in the microcontroller. The problem is that this

requires an additional MAX232 chip, 4 extra capacitors and an

external crystal osciallator for the microcontroller. In any case

it is a lot of extra parts..... and we can avoid them!

We go here for connectivity via I2C because it is reliable and

really easy to build. The amount of data to transfer between PC

and microcontroller is very small (just a few bytes). Speed is

therefore no issue at all.

The LCD display is optional. The software is written such that it

is identical for the hardware with and without the LCD display.

What is I2C?

I2C (prounouce "eye-square-see") is a

two-wire bidirectional communication interface. It was invented

by Philips and they have protected this name. This is why other

manufacturers use a different name for the same protocol. Atmel

calls I2C "two wire interface" (TWI).

Many of you might already be using I2C on their PCs without

knowing it. All modern motherboards have an I2C bus to read

temperatures, fan speed, information about available memory....

all kind of hardware information. This I2C bus is unfortunately

not available on the outside of the PC (there is no physical

connector). Therefore we will have to use something else.

How I2C/TWI works

The datasheet of the Atmega8 (see

references) has actually a very detailed description starting on

page 160. I will therefore present here just an overview. After

this overview you will be able to understand the description in

the datasheet.

On the I2C bus you always have one master and one or several

slave devices. The master is the device that initiates the

communication and controls the clock. The two wires of this bus

are called SDA (data line) and SCL (clock line). Each of the

devices on the bus must be powered independently (same as with

traditional rs232 communication). The two lines of the bus are

normally connected via 4.7K pullup resistors to logically "High"

(+5V for 5V ICs). This gives an electrical "or" connection

between all the devices. A device just puls a line to GND when it

wants to transmit a 0 or leaves it "High" when it sends a 1.

The master starts a communication by sending a pattern called

"start condition" and then addresses the device it wants to talk

to. Each device on the bus has a 7 bit unique address. After that

the master sends a bit which indicates if it wants to read or

write data. The slave will now acknowledge that it has understood

the master by sending an ack-bit. In other words we have now seen

9 bits of data on the bus (7 address bits + read_bit + ack-bit):

| start | 7-bit slave adr | read_data bit | wait for ack | ... data comes here

What's next?

Next we can receive or transmit data. Data is always a multiple

of 8 bits (1 byte) and must be acknowledged by an ack-bit. In

other words we will always see 9-bit packets on the bus. When the

communication is over then the master must transmit a "stop

condition". In other words the master must know how much data

will come when it reads data from a slave. This is however not a

problem since you can transmit this information inside the user

protocol. We will e.g use the zero byte at the end of a string to

indicate that there is no more data.

The data on the SDA wire is valid while the SCL is 1. Like this:

SDA H -\ /---\ /---\ /---\

L \-----/ \---/ \--------/ \------....

SCL H ----\ /-\ /-\ /-\ /-\ /-\

L \---/ \-----/ \---/ \--/ \--/ \-....

| START | 1 | 1 | 0 | 1 | 0 |

One of the best things about this protocol is that you do not

need a precise and synchronous clock signal. The protocol does

still work when there is a little bit jitter in the clock

signal.

Exactly this property makes it possible to implement the I2C

protocol in a user space application without the need for a

kernel driver or special hardware (like a UART). Cool isn't it?

The plan

As said before we cannot use the PCs internal

I2C bus but we can use any external interface where we can send

and receive individual data bits. We will just use the RS232

hardware interface of our PC. In other words our communication

interface is RS232 but we save the MAX232 hardware, capacitors,

etc...

A USB to RS232 converter can be used if you PC does not have a

RS232 port.

The LCD display is optional but if you add one then you can use

this as well as a standalone thermometer with local LCD display.

The temperature sensor

NTCs are small and cheap with reasonable accuracy |

It is possible to get already

calibrated temperature sensors (some of which talk I2C ;-) but

they are quite expensive. NTCs are cheaper and almost as good

even without individual calibration. If you calibrate them a bit

then it is possible to achieve accuracy behind the decimal

point.

One problem with NTCs is that they are non linear. It is however

just a matter of semiconductor physics to find the right formula

to correct the non linear curve. The microcontroller is a little

computer therefore mathematical operations are not a problem.

NTCs are temperature dependent resistors. The value R of the NTC

at a given temperature is:

T or Tc is the temperature value that we are looking

for. Rn is the resistive value of the NTC at 25'C. You can buy

4k7, 10K, ... NTCs so Rn is this value.

T or Tc is the temperature value that we are looking

for. Rn is the resistive value of the NTC at 25'C. You can buy

4k7, 10K, ... NTCs so Rn is this value.

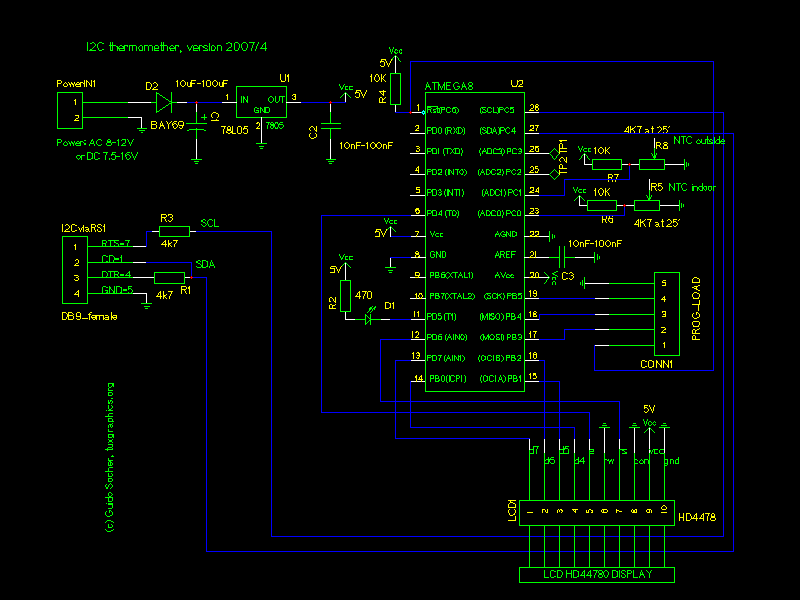

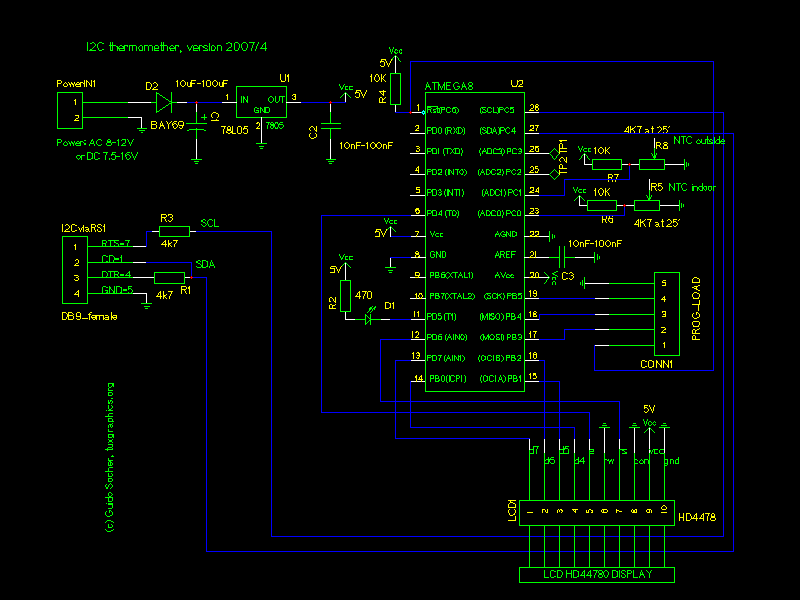

The circuit

Most of the components are actually for the

power supply part. We need a stable reference voltage for the

NTCs otherwise the temperature readings will not be accurate.

There is also an LED connected. It does not cost much and is

really useful for basic debugging and initial hardware test. The

hardware test program test-led.c just causes the LED to blink and

is part of the software package (see download at the end of this

article).

The analog to digital converter in the microcontroller is used to

measure the voltage on the NTC which will then be converted into

a temperature value.

The Atmega8 has two options on what is used as a reference

voltage for the analog to digital converter. It can use either

the 5V (AVcc) or an internal 2.56V reference. For the inside

temperatures we will not need a temperature range which is as big

as for the outside sensor. +10'C to +40'C should normally be

sufficient. We can therefore use the 2.56V reference when we

measure the indoor sensor. This gives very high accuracy as the

1024 possible digital values are then spread over only 0-2.56V

that is we get a resolution of 2.5mV (more accurate than most

digital voltmeters!).

The CD-pin on the RS232 is an input line and it is connected to

SDA on the I2C bus. We use it to read data from the

microcontroller. DTR and RTS are output lines. When the PC puts

data-bits on the SDA line then it just toggles DTR. The

I2C-master (here the linux PC) controls the SCL (clock) line. In

other words the clock line is an output line on the rs232.

Circuit diagram. Click on the diagram for a more detailed view

in PDF.

Note: The LCD display is optional. Just connect nothing if you do not want

to use the LCD display.

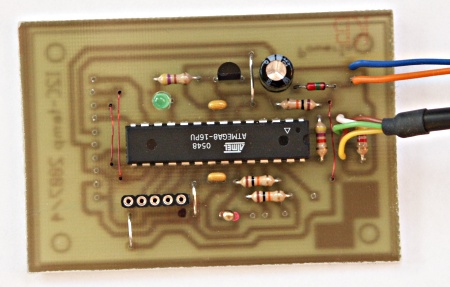

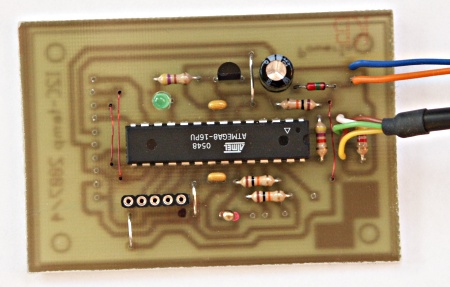

Putting everything together

When you assemble the circuit

then pay attention to the parts where polarity is important:

Electrolyte capactitors, the diode, 78L05, LED and the

microcontroller.

Before you solder the microcontroller onto the board you should

verify the power supply part. If this does not work you will not

only get incorrect temperature readings but you may also destroy

the microcontroller. Therefore connect external power (e.g a 9V

battery) and verify with a voltmeter that you get exactly 5V on

the socket pin of the microcontroller. As a next step connect the

circuit to the rs232 port of your linux PC and run the porgram

i2c_rs232_pintest with various combinations of signals.

i2c_rs232_pintest -d 1 -c 1

i2c_rs232_pintest -d 0 -c 1

i2c_rs232_pintest -d 1 -c 0

This program sets the voltage levels on the RTS (used as SCL,

option -c) and DTR (used as SDA, option -d) pins of the rs232 port.

The rs232 port has voltage levels of about +/- 10V. Behind the

Z-diode you should however measure only -0.7 for a logical zero and

+4-5V for a logical one.

Insert the microcontroller only after your circuit has passed the

above tests.

The complete circuit without LCD display

Using the I2C communication

Download (see references) the

linuxI2Ctemp tar.gz file and unpack it. The I2C communication is

implemented in 2 files:

i2c_avr.c -- the i2c statemachine for the atmega8

i2c_m.c -- the complete i2c protocol on the linux side

I have given the atmega8 the slave address "3". To send the

string "hello" to the atmega8 you would execute the following C

functions:

address_slave(3,0); // tell the slave that we will send something

i2c_tx_string("hello");

i2cstop(); // release the i2c bus

on the microcontroller side you would receive this "hello" string with

i2c_get_received_data(rec_buf);

Very easy. Reading data from the microcontroller is similar.

Look at the file i2ctemp_avr_main.c to see how it works when the

temperature readings are done.

How warm is it?

To compile and load the code for the

microcontroller run the following commands from the linuxI2Ctemp

package directory.

make

make load

Compile the two programs i2c_rs232_pintest and i2ctemp_linux

make i2c_rs232_pintest

make i2ctemp_linux

... or just use the pre-compiled versions in the "bin"

subdirectory.

To read temperatures simply run:

i2ctemp_linux

... and it will print indoor and outdoor temperatures. To

make this data available on a website I suggest to not directly run

i2ctemp_linux from the webserver because the i2c communication is

very slow. Instead run it from a cron job and write from there to a

html file. An example script is included in the README file of the

linuxI2Ctemp package.

The LCD display

For the LCD display we use a HD44780

compatible display as it was already used in previous articles.

These displays are very easy to use in combination with

microcontrollers because you can send them ASCII characters.

I use the same LCD driver code as in all previous articles. The

files which implement this LCD driver are lcd.c lcd.h and

lcd_hw.h. They are in the package which you can download at the

end of this article. The interface for this code is really easy

to use:

// call this once:

// initialize LCD display, cursor off

lcd_init(LCD_DISP_ON);

// to write some text we first clear

// the display:

lcd_clrscr();

lcd_puts("Ok the LCD");

// go to the second line:

lcd_gotoxy(0,1);

lcd_puts("works!");

The software is written such that it works with both 16x2 and

20x2 LCD displays.

There is also a test-lcd.c program which can be use to test the

LCD display. After loading the corresponding test-lcd.hex file

into the microcontroller you should see "=OK=" on the display.

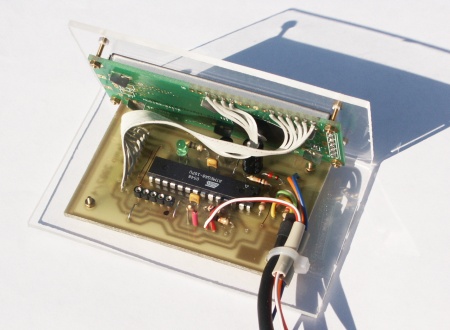

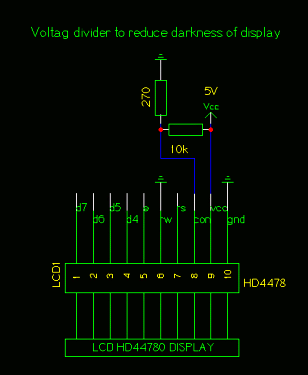

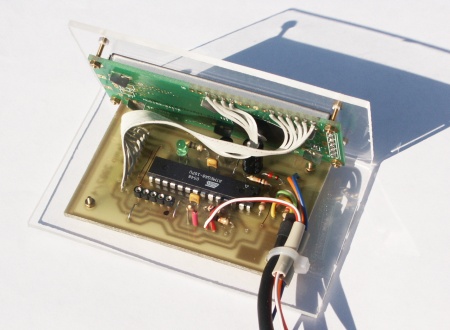

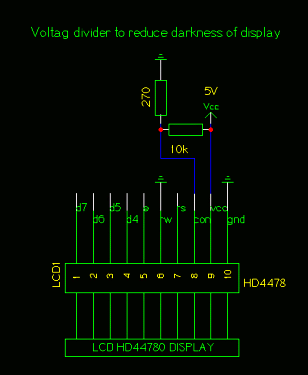

The complete circuit with LCD display

The LCD display has a contrast pin. Connecting this pin to GND results

in maximum darkness of the display. The total darkness off the display

depends however very much on the make of the display, the viewing angle

and power supply voltage level.

A change of 0.2V results already in a noticeable change of display darkness.

In most cases it is quite OK to connect the "CON" pin directly to GND.

If that gives however a too dark display then add a voltage divider as

shown here:

Since the CON pin is normally directly next to the VCC pin the

easiest solution is to solder the 10K resistors directly to the display and

insert the 270 Ohm resistor in the wire that goes to the CON pin.

A little GUI

For those wo would like to have GUI on their

desktop I made a really simple gui. It consists just of 2 labels

which are used to display the two line output of i2ctemp_linux

command (the i2ctemp_linux is the command which read the

temperatures from the circuit via I2C):

Now we have a really cool thermometer. With a lot of

possibilities:

- You can read the temperature locally from the display

- You can have a little GUI on your desktop

- You can write values with a cronjob to a log file to get

long term statistics

I will now use the rest of this ariticle to explain a bit

the internals of the software.

Makeing temperature data available on the web

You should

not run i2ctemp_linux directly from the webserver. It is too

slow. Instead add a contab entry which runs a script to generate

an appropriate webpage e.g every 15 minutes:

The script to run from contab:

#!/bin/sh

webpagefile=/home/httpd/html/temp.html

echo "<h2>Local temperatures</h2><pre>" > $webpagefile

i2ctemp_linux | sed -e 's/i=/inside /;s/o=/outside /' >> $webpagefile

echo "---------" >> $webpagefile

date >> $webpagefile

echo "</pre>" >> $webpagefile

Copy the i2ctemp_linux program to /usr/bin and run the above

script e.g from a crontab entry which looks like this (load a file

containing this line with the command crontab):

1,15,30,45 * * * * /the/above/listed/scriptfile

How it works: Analog to digital conversion

The Atmega8

supports two modes. In the continous mode it permanently measures

the analog signals and just triggers an interrupt when the

measurement is ready. The application software can then use this

interrupt to quickly copy the result from two registers into a

variable.

The other mode is the so called single shot mode. Here only one

conversion is done. The single shot mode is still pretty fast.

Including the setup time of the required registers before and the

reading out you can still get 100 conversion per second. This is

more than fast enough for us. So we use this mode because it is

easier to use in functional programming. We just call a function

and it returns the ADC values.

The Atmega8 has analog input pins ADC0 to ADC3. In addition to

this there are the pins AGND (analog ground, connected to normal

ground), AREF (the reference voltage) and AVCC (connected to

+5V).

During analog to digital conversion the analog signal is compared

with AREF. An analog signal equal to AREF corresponds to a

digital value of 1023. AREF can be any external reference between

0 and 5V. Without the use of an external reference you can still

do precise conversion by either using an internal reference

(2.56V) or AVCC. What is used is decided in the software via the

REFS0 and REFS1 bits in the ADMUX register.

The analog to digital converter can convert one of the input

lines ADC0-ADC3 at a time. Before you start conversion you have

to set bits in the ADMUX register to tell the chip which channel

to use.

A simple analog to digital conversion would then look like this:

unsigned char channel=0; // measure ADC0

int analog_result;

// use internal 2.56V ref:

ADMUX=(1<<REFS1)|(1<<REFS0)|(channel & 0x0f);

// ADCSR: ADC Control and Status Register

// ADPS2..ADPS0: ADC frequency Prescaler Select Bits

// ADEN: Analog Digital Converter Enable, set this before setting ADSC

ADCSR=(1<<ADEN)|(1<<ADPS2);

// start conversion

ADCSR|= (1<<ADSC);

while(bit_is_set(ADCSR,ADSC)); // wait for result

adlow=ADCL; // read low first !!

adhigh=ADCH;

analog_result=((adhigh<<8)|(adlow & 0xFF));

As a software designer you must watch out that you read the

lower 8 bits first as the microcontroller has some locking

mechanism to simulate "atomic" reading. After this we have the

analog to digital conversion result available as a number in the

analog_result variable. This can the be used elsewhere in the

program. Very easy.

The ADPS register (ADC clock pre-scaler bits) must be set such

that the clock frequency divided by the pre-scale factor is a

value between 50 and 200 KHz. The division factor is 2^ADPS (two

to the power of the ADPS bits value). The above setting (ADPS2=1,

ADPS1=0, ADPS0=0 = decimal 4 -> 2^4 = 16 -> division factor

= 16) is good for a clock frequency of 1MHz.

The Atmega8 has several possibilities for reference voltage

selection. The reference voltage is compared against our analog

input voltage. It is the voltage that corresponds to a digital

value of 1023.

| REFS0=0, REFS1=0 |

use external AREF, Internal Vref turned off |

| REFS0=0, REFS1=1 |

AVCC with optional external capacitor at AREF pin |

| REFS0=1, REFS1=1 |

Internal 2.56V Voltage Reference with (optional) external

capacitor at AREF pin |

An optional capacitor on the AREF pin can be used to

suppress noise and stabilize the AREF voltage (in case you switch

between differnt voltage levels: remember that it needs time to

charge the capacitor).

How it works: I2C communication, Atmega8 part

I explained

already in the beginning of this article how this I2C protocol

works. Let's now have a look at the software. The Atmega8 has

hardware support for I2C communication. Therefore you do not

actually need to implement the protocol. Instead you need to

implement a state machine. This tells the Atmega8 what to do

next. Here is an example:

An I2C packet with our own slave address was received. The

Atmega8 will now call the function SIGNAL(SIG_2WIRE_SERIAL) with

the status code 0x60 (for other events we would get other

codes).

--> We must now set a number of registers to tell the Atmega8

what to do next. In this case we will tell it: receive the data

part and acknowledge it.

When the actual data was received we will get called with status

code 0x80.

--> Now we read the databyte and tell the Atmega8 to

acknowledge the next data byte if it comes.

When the communication is over we get a status code 0xA0 (stop

condition) and we can tell our application that a complete

message was received.

The whole state machine for the I2C slave mode and all possible

states are explained in the datasheet of the Atmega8 on page 183

(see link in reference section at the end of the article).

Transmitting data is very similar. Have a look at the code!

How it works: I2C communication, Linux side

First a word

about the hardware. Even though I2C is a bus we only use a point

to point connection between one slave and the Linux PC as I2C

master. We can therefore save the pullup resistor as long as the

slave can still pull down the line without causing a short

circuit. We just put a 4.7K resistor into the line.

The voltage levels must be adjusted. The voltage levels on the

RS232 side are +/- 10V. This would be too much for the Atmeag8

but it has also an internal over voltage protection diode. We

limit with the 4.7K resistors the current so much that it is

sufficient to relay that protection diode for over voltage

protection.

The Linux I2C software implements basically a complete I2C stack.

This is because I wanted to have a little command line utility

which does not need any special library or kernel module. It

should just work on its own.

If you look into the file i2c_m.c (see download) you can see that

really every I2C message is build bit by bit.

To generate the "bits" we must toggle the physical pins on the

rc232 interface. This is done with ioctl calls:

// set RTS pin:

int arg=TIOCM_RTS;

ioctl(fd, TIOCMBIS, &arg);

... or to produce a zero:

// clear RTS pin:

int arg=TIOCM_RTS;

ioctl(fd, TIOCMBIC, &arg);

If you want to port this stack to a different OS then you

just change these lines. The rest is plain C and independent of the

operating system.

How to mount the outdoor sensor

The

outdoor sensor must be protected properly against rain (and sun).

You can try to wrap it into some plastic but I don't recommend

this. No matter how tight you tie it, water will eventually come

in and stay in there. The NTC is quite robust and it does not

matter if it gets a bit humid as long as it can dry again. Use a

up-side down mounted tablet tube which you leave open at the

bottom. This way any water will be able to get out again.

Conclusion

I am now using the thermometer for 2 years and

I really like it because you can read it out directly on the

display and you have the possibility to store all the data on

your PC. You can view it there, draw graphs do statistics. Really

cool.

The I2C protocol requires very little extra hardware and is

optimized for transmitting or receiving small amounts of data.

That is exactly what we need when we want to communicate with our

own microcontroller hardware. It is really a very nice

solution!

References

© Guido Socher, tuxgraphics.org

2007-05-14, generated by tuxgrparser version 2.55

![[Illustration]](../../common/images2/article07051/I2Ctemp-20074-title.jpg)